So since my last post the girls and I have got a system down pretty much. We continued to work through the little mini-projects putting them together to get a lot of it put together.

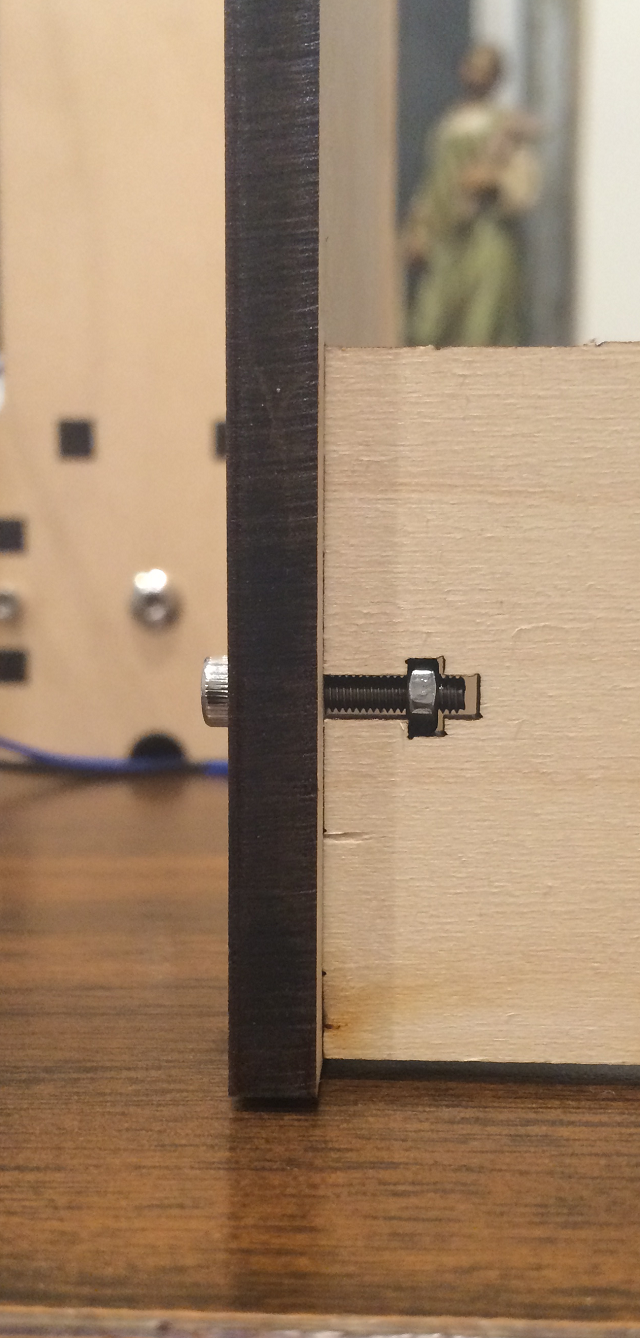

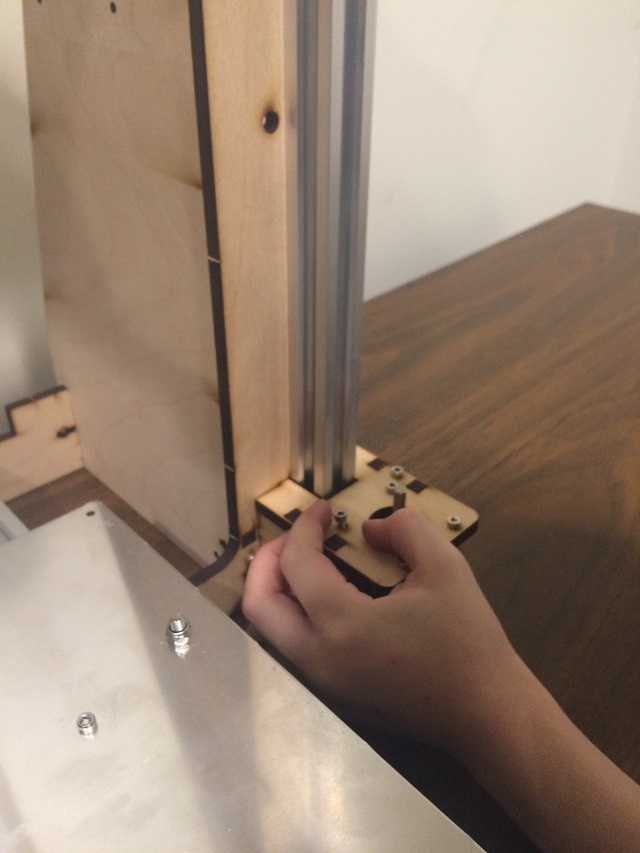

One funny thing I noticed while me and the kids were working on this is the way the wood is held together. If you look at the picture below you will see them. It is a tiny nut slid into the wood on a little cross then the screw bolts through the joining piece to keep the wood together.

Now me and the girls really liked the little crosses all over the place, but I didn’t understand why the manufacturer just wouldn’t want me to glue it. In the last post things seemed to go together pretty nicely without any trouble and it isn’t like we would ever want to go through the trouble of dismantling the printer, would we?

Side Note: If you noticed St. Joseph in the back ground that was not really on purpose, his statue is behind my work desk in my office. Me and St. Joseph have an agreement; if he is in a picture I take on a project, I can’t crop him out unless there is a good reason. After all, he is the patron saint of work.

Well now why would we want to take it apart? I learned early on. Remember this picture from the last post?

Those are our Z motor brackets and they are a mess. If I would have glued those together that would have been it. It is hard to tell from the picture, but they are both wrong. That was particularly confusing for me to fix. There was all sorts of stuff me and the girls put together wrong, but I didn’t realize it until later. So… In a nutshell, little crosses with nuts and bolts… Great idea!

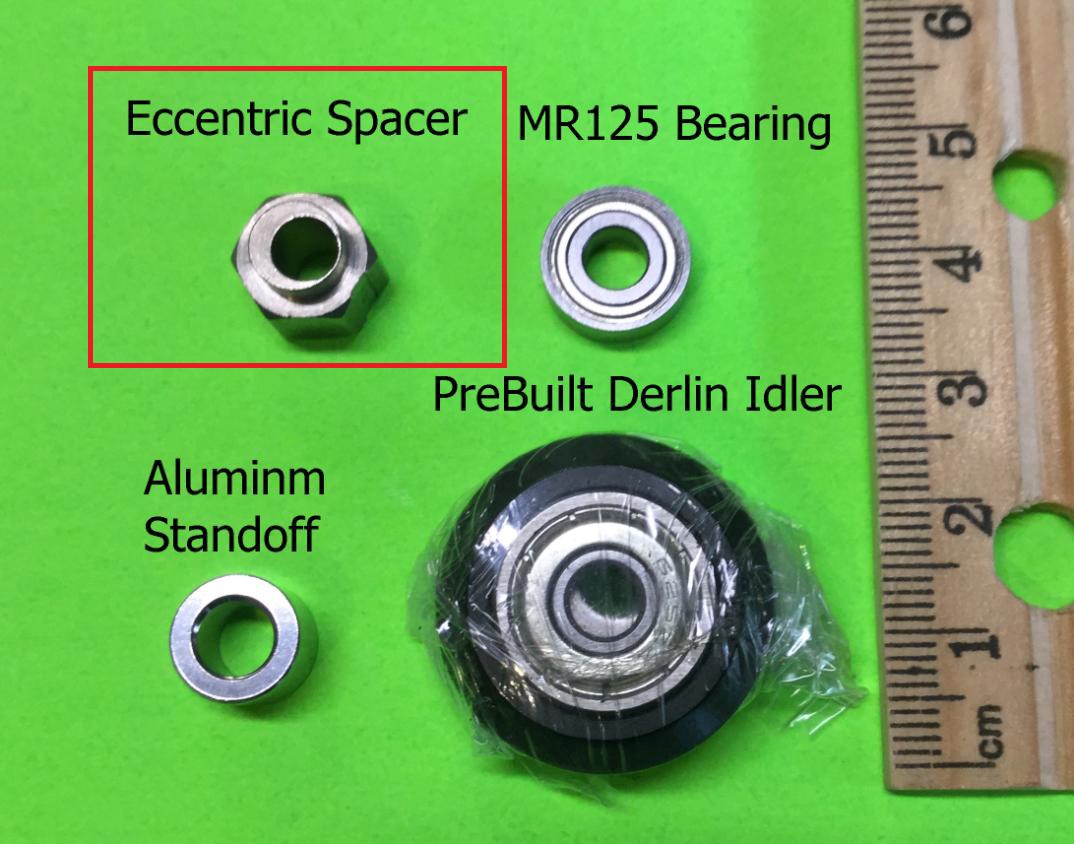

Here is another thing I didn’t understand that I had to learn about. I was totally confused when we installed the first “Eccentric Spacer”. Here is a picture of one below.

When we installed the first one I thought to myself, “That is a really odd looking part. (yes… eccentric even) That is probably what gets put into devices when some measurement didn’t go right and they have to adjust the final product as kind of a “fix”. Of course I was wrong. Those suckers are strategically placed so we can tighten the carriages that move across the different axises (What is the plural for axis anyway… I should know this. I probably should have known what an “eccentric spacer” is too, but I didn’t.) Oh well… no time to be embarrassed for what I should know already… we must press on!

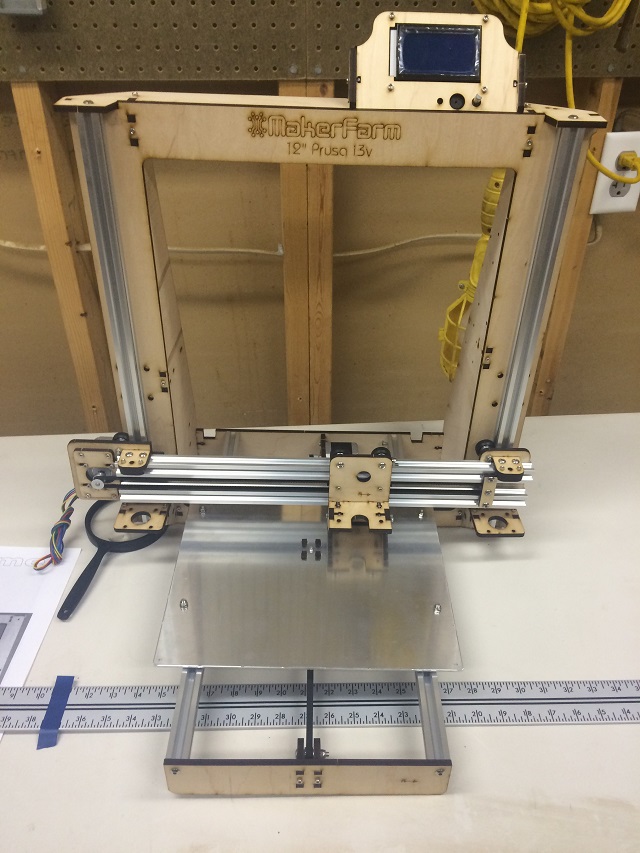

Anyway after a few evenings we got a lot of our parts put together and now it looks like something. At the top you notice a display panel. That will tell us important stuff I am sure. I can’t wait to see it turn on!

The next step in the project is to get some insulation for to put between that aluminum bed. I have no idea what to do about that now. It also requires that I get some glass. So I go to the hardware store.

On my way to the hardware store I call my buddy Charlie who already built one of these things to ask him about insulation. People would buy some sort of insulating blanket, so I thought I would ask him what he did. I also wasn’t sure what to do about the glass.

Charlie said he had some insulation for me and would just give it to me. He explained it to me and it sounded quite technical so I put my brain into the same mode when my accountant or financial adviser talks to me because I am a bit slow and not ready to understand and have to wait until tax time to actually listen for real. What I heard from Charlie is this, “Oh… that is no problem, I have some extra insulating material that you can use”. I thought to myself and stopped listening (I know rude, right?), but in my defense Charlie already alleviated my fears on where to get insulating material and I got all worried about how I was going to get and cut the glass. When I started writing tonight I asked Charlie for more information on the insulation I would be using so I could tell people about it. Here is what he said:

- It is “welding curtain” from a company called Avsil.

- It can stand tempuratures up to 1800 degrees farenhight.

- It contains no asbestos.

He even sent me a link:

http://www.avsind.com/tdspdfs/AVSIL84CH.pdf

Me and Charlie had a regular work project to work on in a couple of days so it would work out well. For the glass, he said just buy regular window glass.

Now I was hoping that they would cut it for me, but nope I had to do that myself. Now I remember cutting glass as I did a bunch of that years ago on my old house and I remember not liking it because it seems easy to screw up.

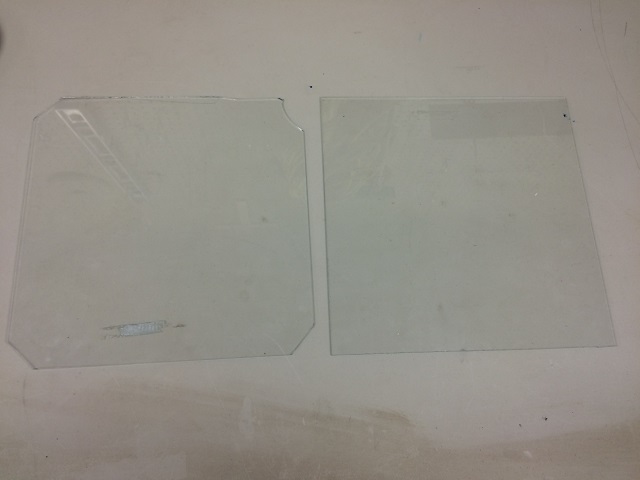

This particular project requires a 12″ by 12″ piece of glass with the corners cut off so they wont’ get in the way of some mounting bolts in the corners of that aluminum plate.

So I buy a 36″x12″ piece of window glass and a glass cutter (I know I will never find mine because I haven’t seen it in literally 7 years at least. I have to assume that one is gone forever). If I am careful I will have three 12″ by 12″ glass pieces for the aluminum plate.

So here is what I end up with. I completely ruined one of the 3 panes of glass for the bed so that went into the garbage. Then I cut the corners off the next one and screwed up one corner. Now I am gun-shy and decide to leave the last “perfect” 12″ x 12 ” piece to the right for later in case I break the ugly one on the left with the messed up corner.

Now the girls couldn’t help with that part. So we press on with some other things. Like installing stepper motors!

The Z motor brackets we messed up earlier hold a pair of motors one on the left and one on the right that bring up and down the carriage that will end up holding our material (I had to look that up because 3D design is something that is totally new to me). But I do know a lot about motors and this part is fun.

So I have Hannah install the left Z motor.

And Cordie installs the right Z motor.

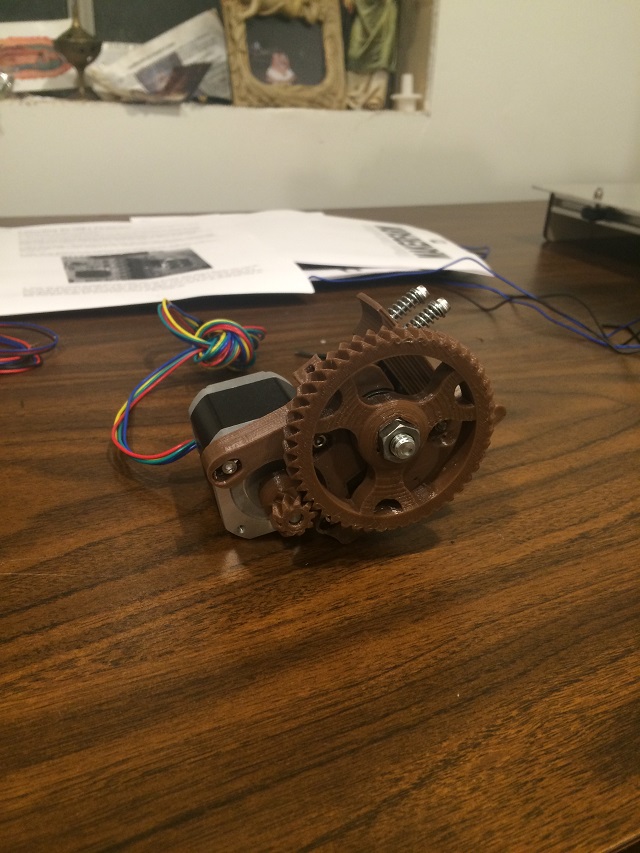

After that we build one of these! Now why did I put an explanation point after “these” it is because those gears you see, I can tell, were printed on a 3D printer. I am supposed to print those out as my first serious project with this thing (I will do that without the kids to test the printer and save the surprise for something that will be more meaningful to a child).

So until I get the welding curtain from Charlie I need something else to do. I scroll down to the section called “Electronics Setup”. Now this is where I hopfully will have the most fun.

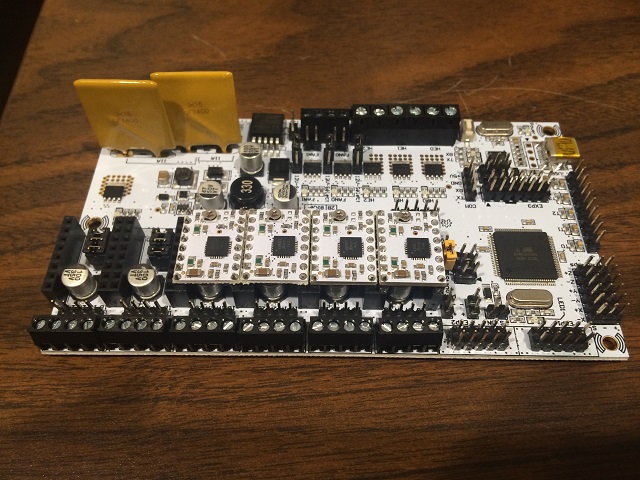

The next step I will do is start working with the main system board of the unit. This is the brains of this whole operation, it is called a Rhumba board.

Now there are all sorts of connectors on that thing. I am not sure what to plug into them. The instructions tell me to load the firmware for my display first and they are pretty specific about what versions to put on it. It tells me first to install a driver on my PC for that first step.

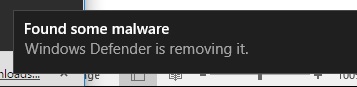

Now I install what is called “firmware” on devices all of the time. I am so old that the term “firmware” used to mean that you literally install a new physical chip into a device to get it updated (Think “firm” vs. “soft” ware). I have seen a lot.. But when I downloaded the firmware image to update this board… My PC complained about this:

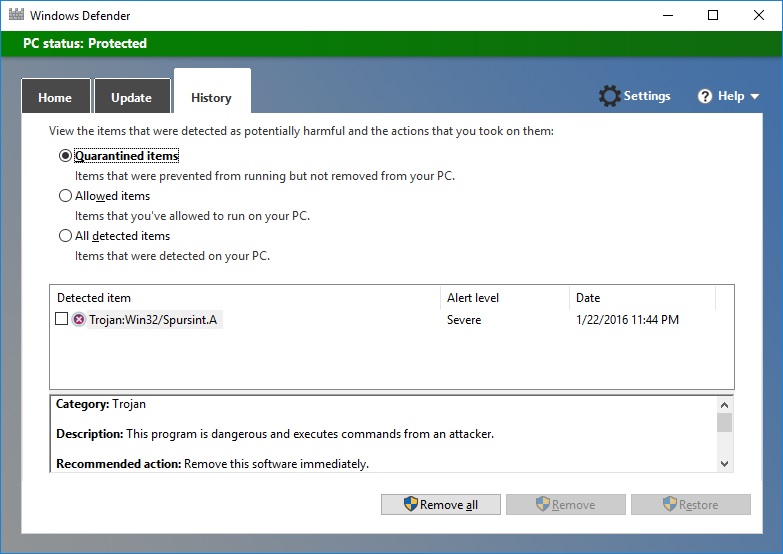

Then I looked into it more and saw this:

Now I have seen a lot, but have never seen that before. Now I am paranoid.

I wasn’t expecting that at all. Now these two things may be “false positives” but I do have to be safe. I will stop here because of obvious reasons. I am not sure at this point how I am going to address this issue. For a guy who owns a security company to click on a link that had potential to give him a virus… Oh… No no no… That is bad bad bad. It is a good reminder, we are all just a click away from a really bad day. Maybe I dodged a bullet there. Maybe it was a false positive… I will do some poking around and find out.

I will tell everyone what I do to get past it in the next post.

Recent Comments