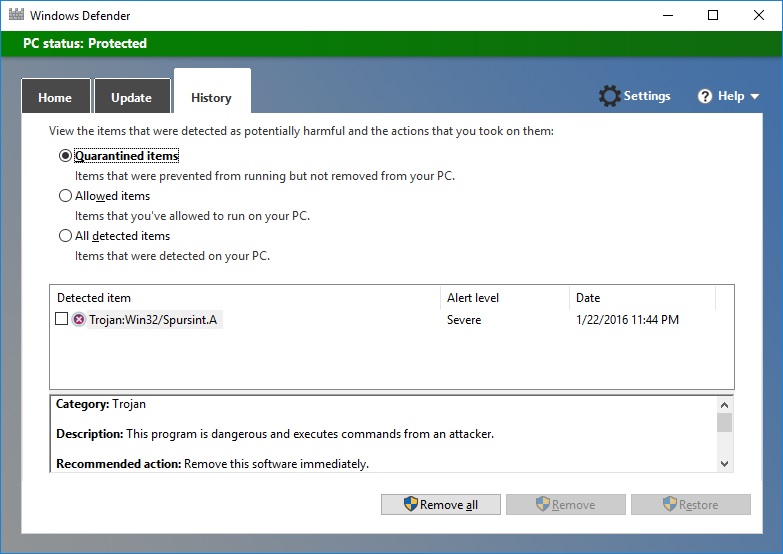

OK… I think we lost Hannah’s interest. She is my eight year old and most capable. My wife told me tonight she was hit with the “creative bug” and she just wants to sew. This situation is my fault because I ran into things that I didn’t understand. First I wasn’t sure what to do about the false virus warning. And then there was the whole glass thing where I didn’t want them to get cut, so they weren’t working on this project. And the workshop is still a total mess, it is no wonder my girls aren’t thinking about it anymore.

I have to figure out how to turn this around and get my girls plugged back in.

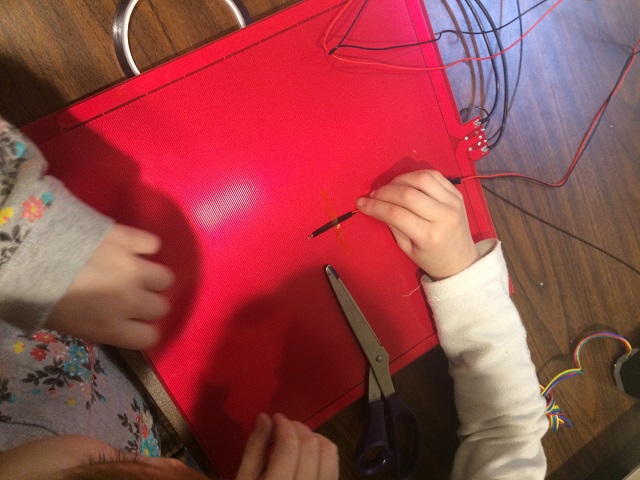

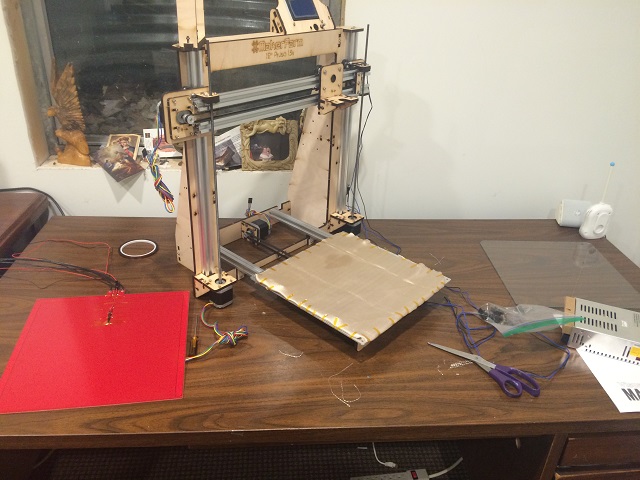

I did get some work out of them today though. The heat bed that keeps the printing surface nice and hot while the machine is doing it’s thing needs a thermistor. So we install that.

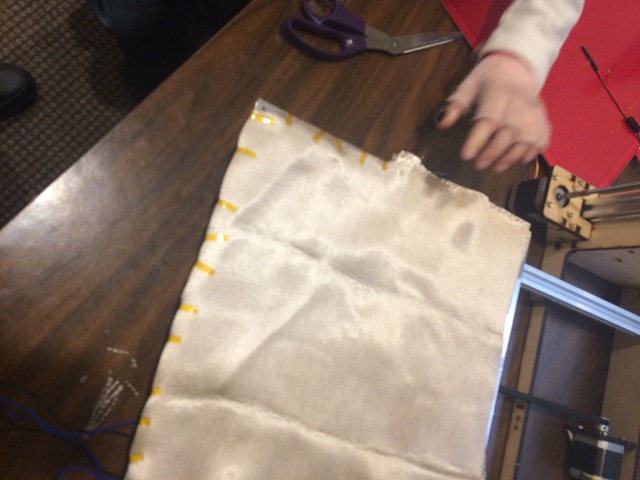

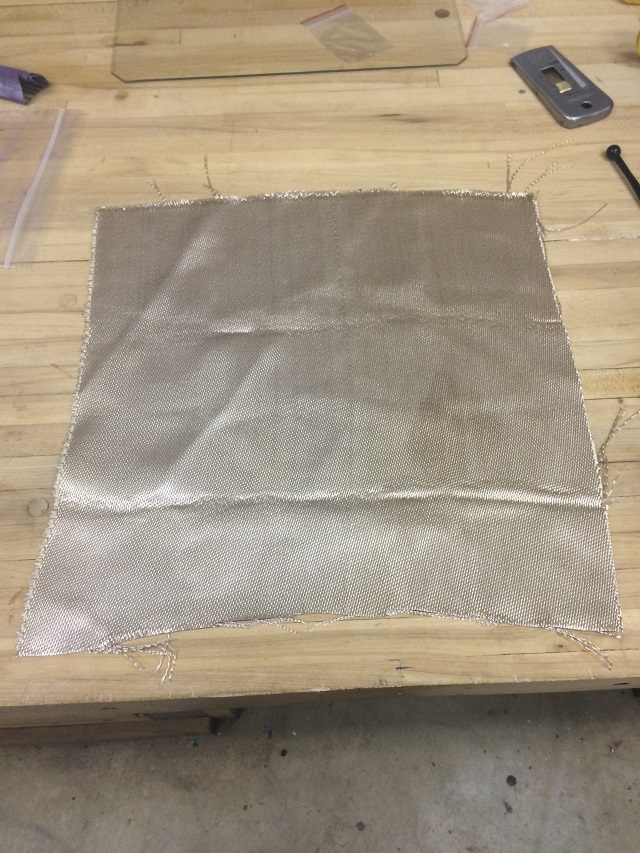

Then the girls start working on the insulation (Welding Curtain). That keeps the heat from dissipating out the bottom of the heat plate.

While all of this important work was going on Kasia decided to open my tool drawer and pull out the alligator clips on my multimeter. She must have thought they looked like some sort of monster or scary animal and just started growling, “Rar….Rar…” It was pretty funny.

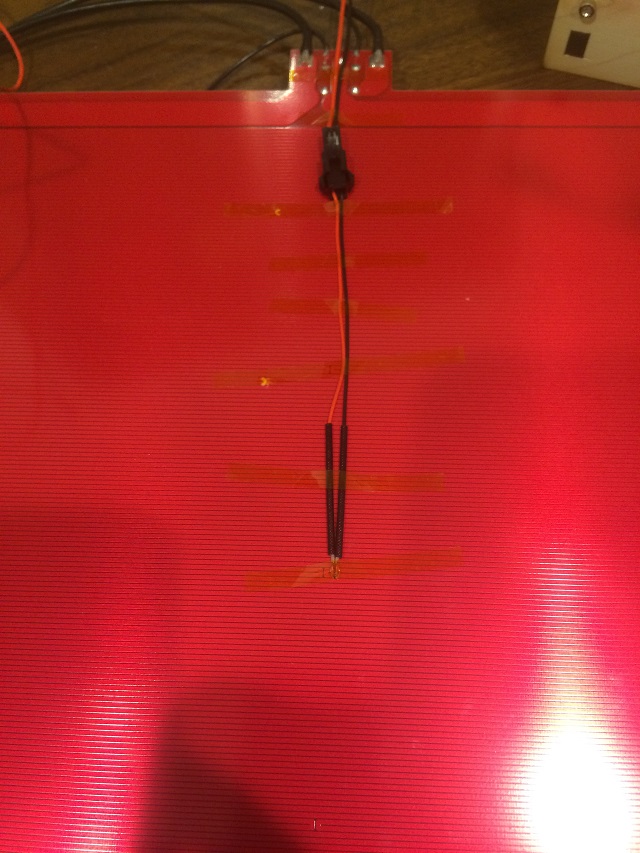

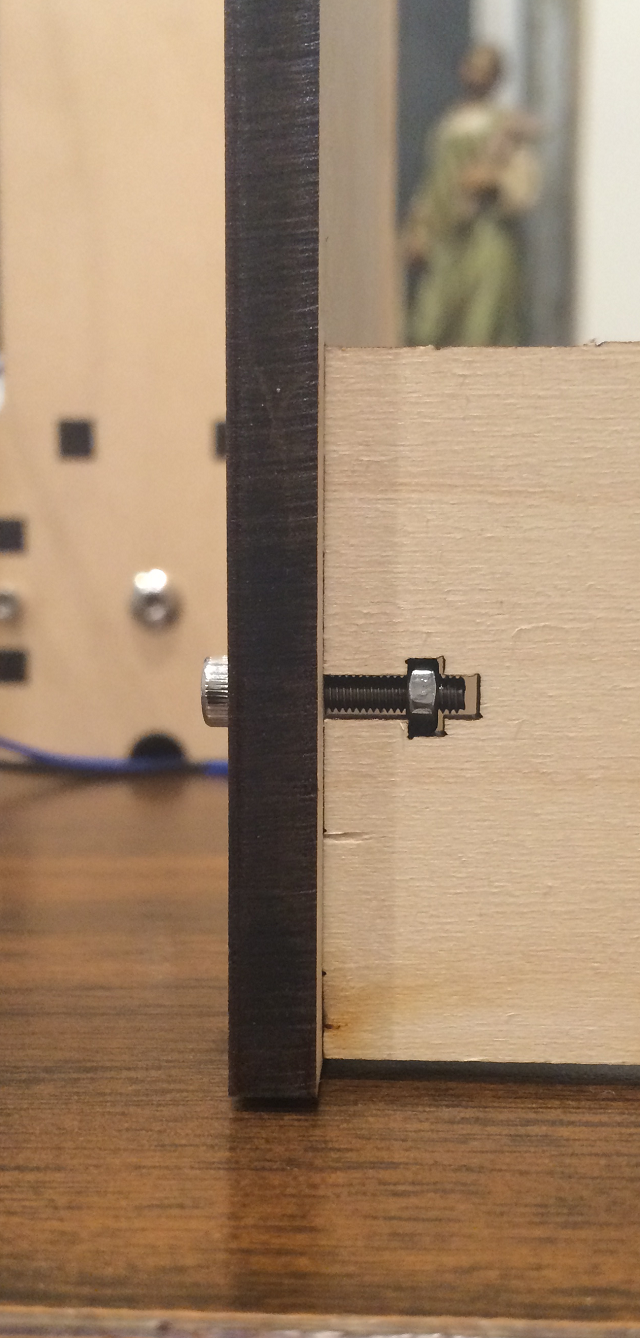

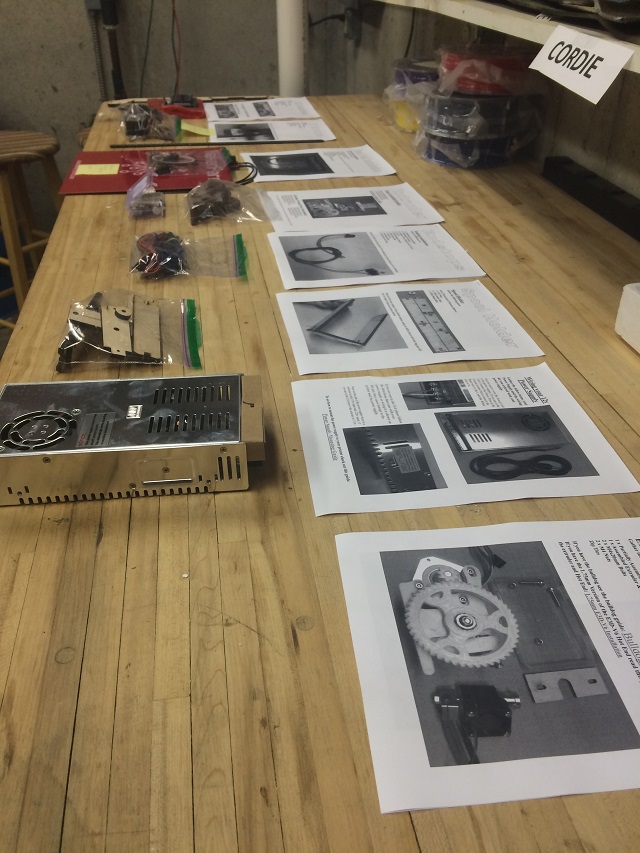

After the girls went to bed I had another look at the heating element. I was concerned that the plastic connector would melt. So I emailed the manufacturer about it. Here is what it looked like.

He said it would be fine, but her personally moves them off the board to get more room for the “Z” high. I emailed him back a simple “thanks” and didn’t let him know my personal secret… I am not totally clear on the whole X, Y, Z and axes yet (Thanks Mom for clarifying the plural of axis earlier).

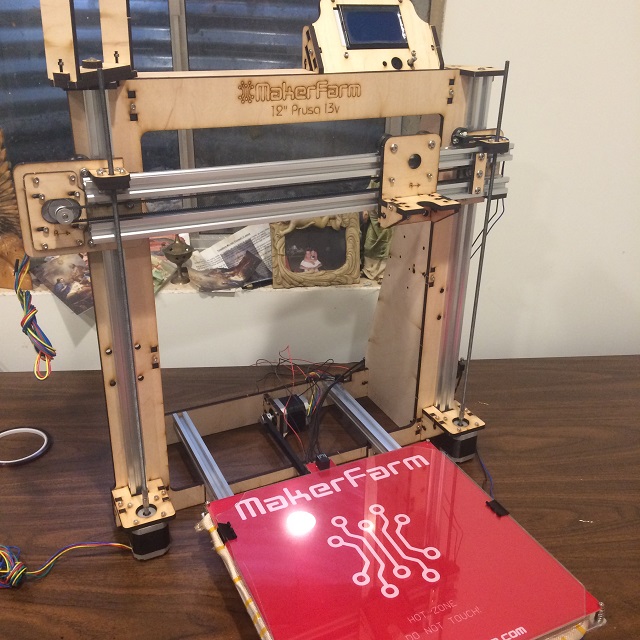

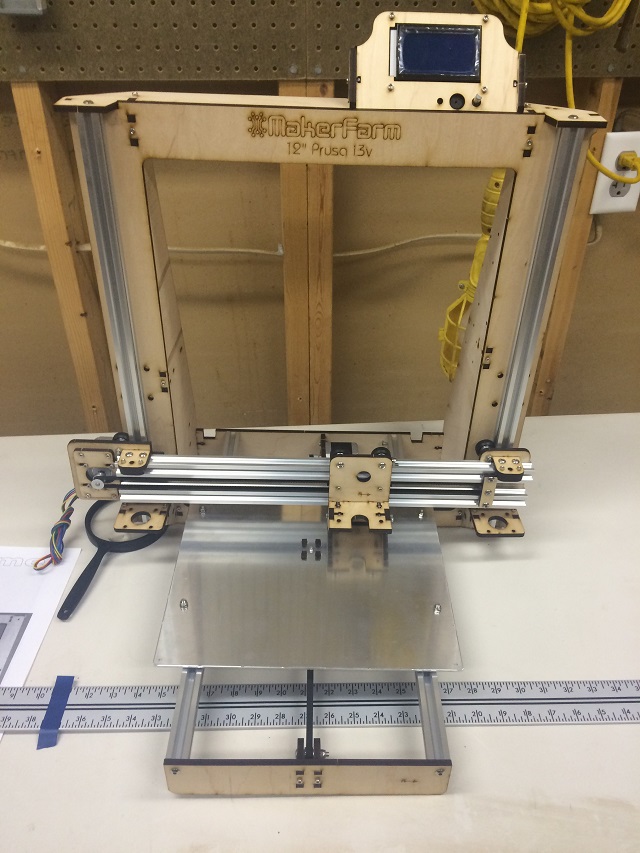

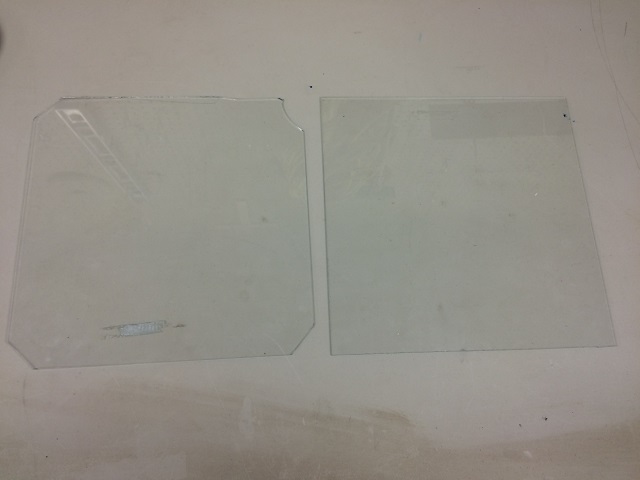

So I fix it. I move the connector off the board to make room for the “Z” high. And here is where it sits for tonight; we have our “perfect” glass, our heating element, our welding curtain/insulation attached to the aluminum plate (BTW – All instructions I have read call it a “bed” not a “plate”).

So that is where I have to leave it for tonight. I am a little discouraged as here are the next steps… And then seem like a lot to me because I am very tired.

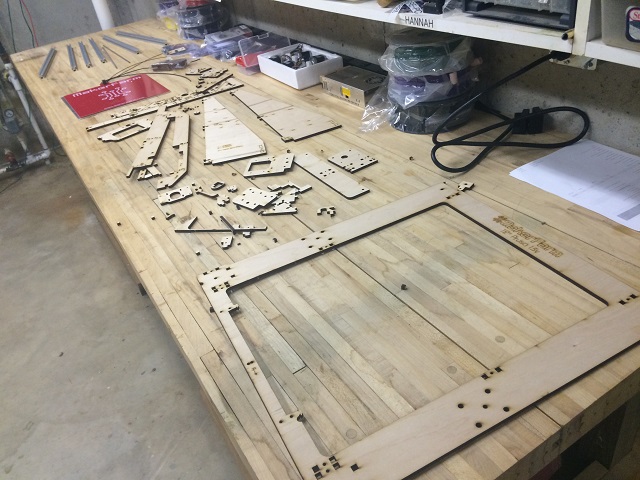

- I have to clean and organize the workshop. It still is a disaster.

- Me and Cordie are going to put together the head bed as Hannah has her own thing going on with sewing (I couldn’t possibly discourage her from her own project for this, or could I?).

- Me and Cordie are going to mount the power supply to the unit.

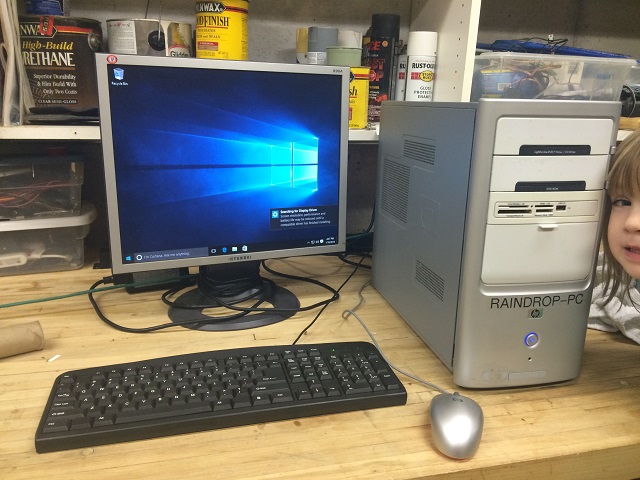

- I still have to put up the “RAINDROP-PC” computer me and the kids built to run this thing.

- I have to create a secure network on my firewall in my house so if there is any weirdo virus that hits this system, it can’t get to my regular work computer (This isn’t actually a big deal, but I have to figure out a good way to do it, so it makes it more of a problem than simply plugging it in).

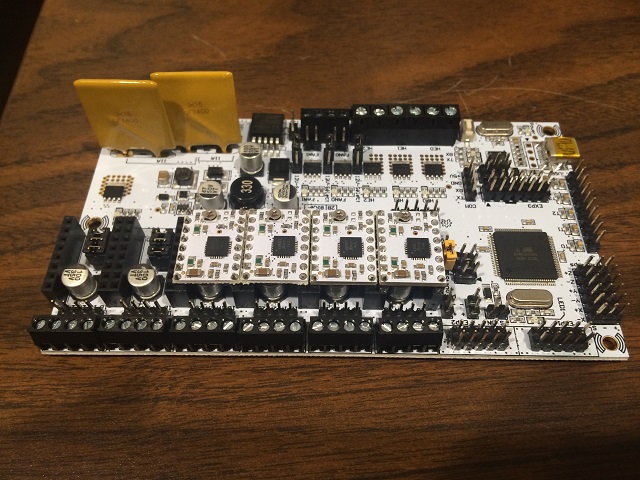

- I have to figure out how to get the correct “code” onto the brains of the system (It is called a Rumba). This is a little annoying because I do this sort of thing all of the time in my normal job. I have to admit though, I am saving this for later because it is the part I am least worried about messing up.

- Finally I have to work with it by myself a little bit to solve a bunch of things that I don’t understand. For example… we haven’t connected anything yet.. no power, no nothing. I am pretty sure all the wires that hang off of it need to be connected somewhere… I haven’t even read that part of the manual yet.

1/25/2016

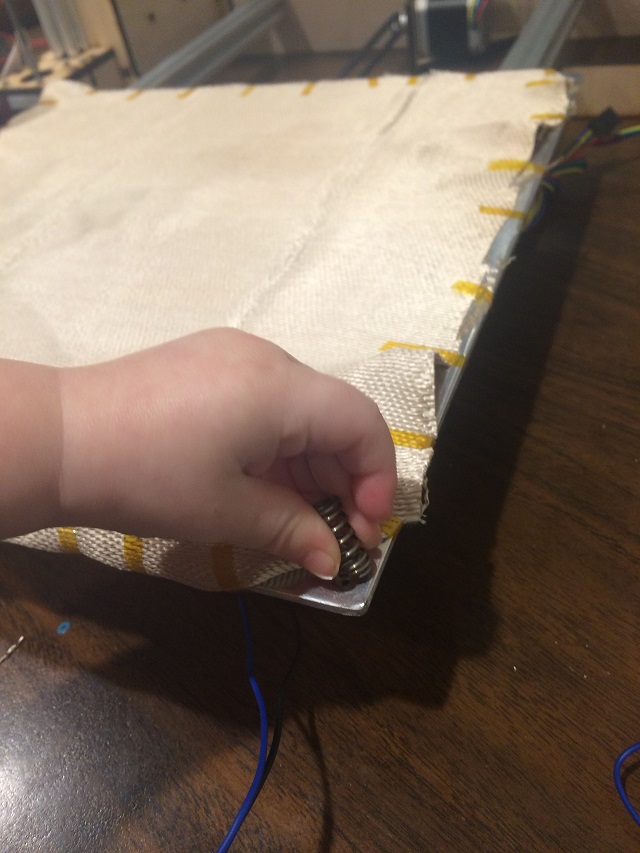

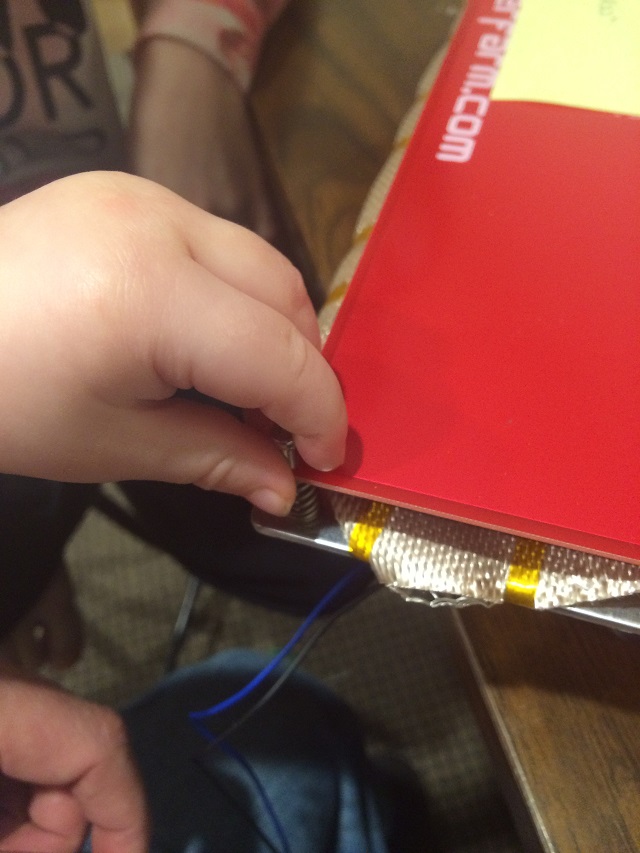

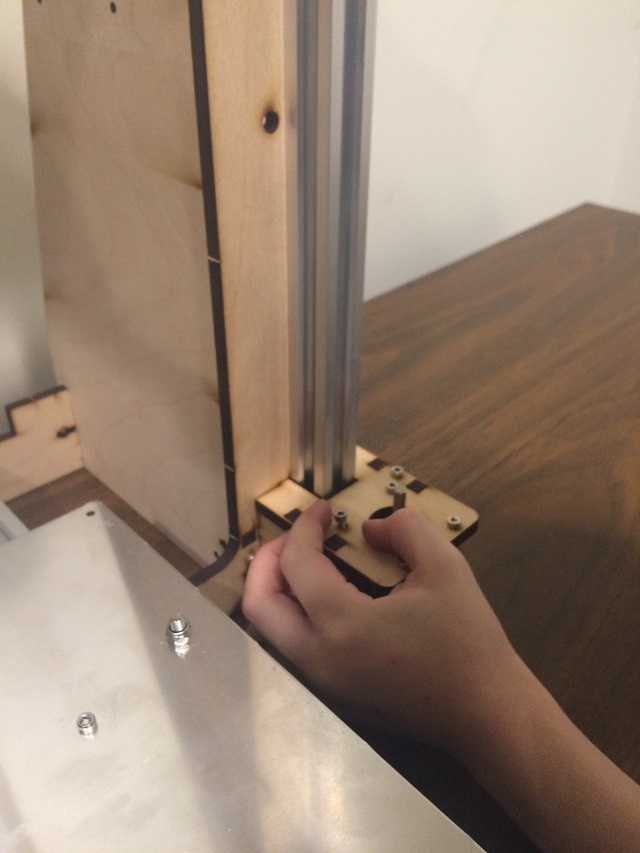

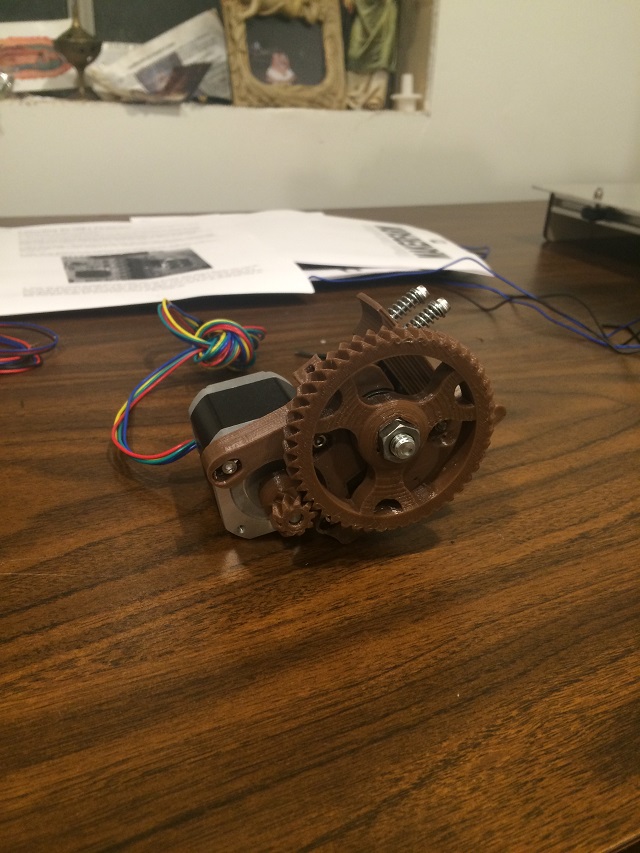

So it was tough getting the girls rounded up to help. They were much more interested in roller skating in the basement than helping. So I did what any good dad would do. I roped my 1 year old Kasia into helping (She doen’t know how to roller skate and I am pretty sure she is afraid of getting knocked down while the girls are, so she is happy to help). Here are some pictures of her helping me put the springs on the bed to attach that heating element. Her little hands are so fat it is funny.

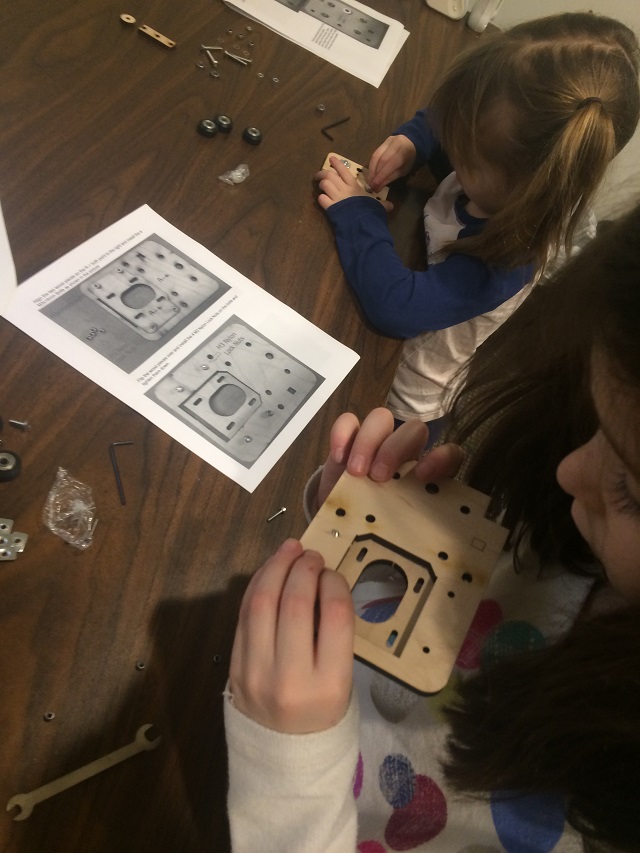

That was really short lived because she is so little. The girls saw the printer being worked on so they pitched in too. Here is Hannah and Cordie helping.

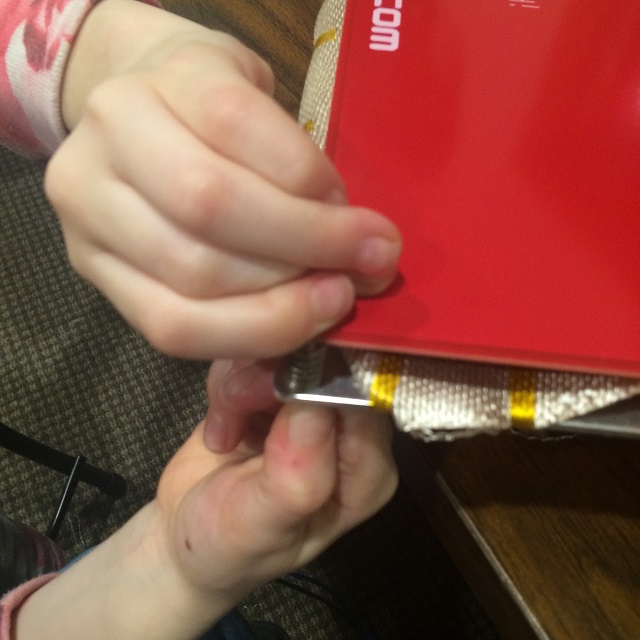

Hannah was the only one that could handle putting tightening the nut and bolt.

And at this point in the project the team kind of hits a wall. We get all set to mount the power supply and I don’t have the correct screws for it. I didn’t buy the power supply from the manufacturer of the printer because there are so many different ways to power the thing up. I bought the recommended one, but it didn’t come with any mounting screws. So… I have to go to the hardware store.

I am starting to get frustrated with me and my teams lack of progress on this. It is none of our fault, it is just that I am reaching the point where I literally have to think hard about each step and the correct approach. The kids can’t really help me do that. When we first started I could look at a step and immediately break it down for the kids to do. Now we are in adult world. When I am installing drivers, updating firmware, making electrical connections, I need to be focused on that and not on instructing the kids. I need some time where I can really focus with this and my schedule this week is full.

Oh… One more quick thing, my “perfect” glass didn’t fit. My junky glass did. So I used junky…

Recent Comments